“Qu”: the backbone of Chinese Baijiu

Explanation of the process of making “Qu”

Renhuai City, located in the northwest of Guizhou Province and in the middle reaches of the Chishui River, enjoys a subtropical humid monsoon climate with an annual average temperature of 16.3 degrees Celsius. With 360 days of good air quality each year, Renhuai provides unique geographical conditions for the development of its liquor industry.

Wineries are scattered along both sides of the “V”-shaped Chishui River Valley, between the two mountains. The area is lush with trees, and the rich, long-lasting fragrance of Baijiu permeates the entire valley town, gradually dispersing with the wind. This region is known as the “World’s Core Production Region for Moutai-flavor Baijiu.”

“Water is the blood of Baijiu, grain is the meat of Baijiu, and “Qu” is the bone of Baijiu” is the essence of traditional brewing.It has the dual functions of saccharification and fermentation.

Tips: “Qu”is Saccharifying starter culture. The starch and sugar in the grain must be fermented to be converted into ethanol, and the fermentation needs a medium to promote the saccharification of the grain, the medium is called the saccharification starter culture, that is, the “Qu.”

High quality wheat

Raw material

The traditional Maotai-flavor “Qu” is prepared from pure wheat. The protein in wheat is decomposed into amino acids and small molecular peptides by the action of microorganisms and enzymes. These substances can not only increase the flavor of the Baijiu, but also regulate the taste and balance of the Baijiu. “Qu” has high requirements on raw materials, the wheat should be full grain, no moth, no pesticides, no mildew, water and starch content should be up to standard.

Detailed explanation of the process of making “Qu”

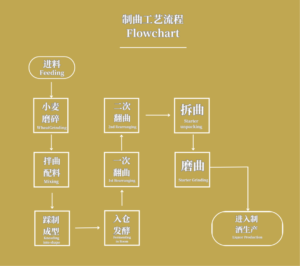

From wheat to “Qu” powder, “Qu” production must go through wheat crushing, “Qu” material preparation, stepping “Qu” billet, “Qu” billet into the warehouse, turning over in the warehouse, dismantling “Qu”, drying storage, grinding “Qu”.

- Wheat crushing

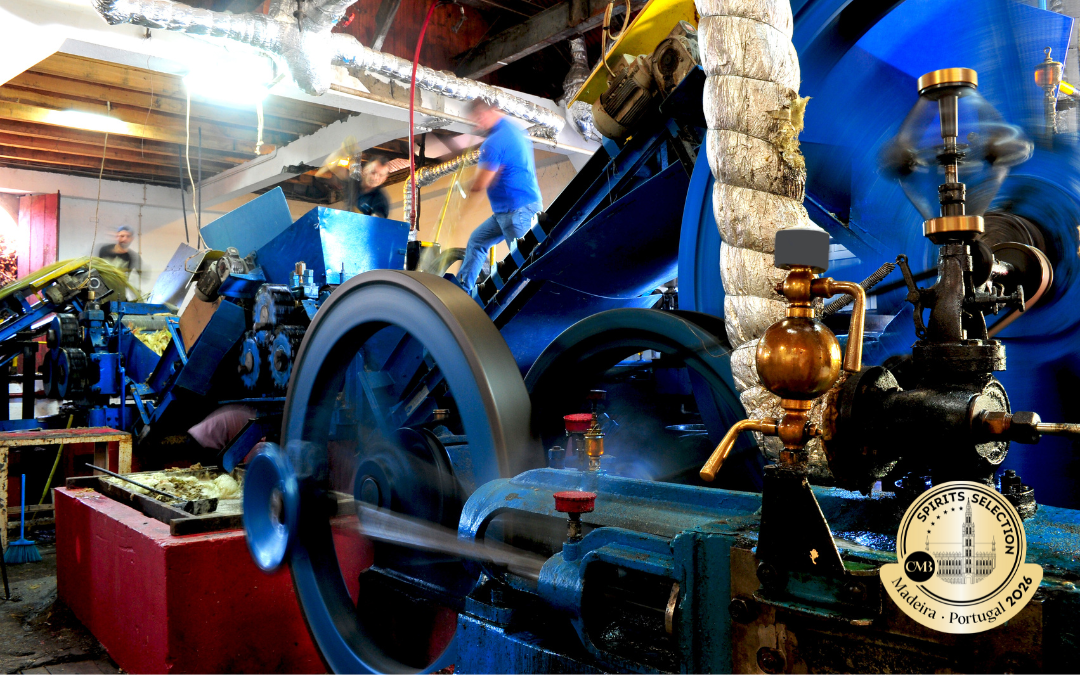

Wheat crushing

First of all, it is necessary to “moisten the grain” according to the soft and hard degree of wheat, so that the skin fully absorbs water, and then it is crushed. When crushing, ensure that the skin is at least 2-3 segments, there is no rough block, and it is appropriate to touch it by hand.

2.Preparation of “Qu” material

When mixing “Qu, add the wheat amount of 4.5%-8% of the “Qu” origin (more than half a year of the old “Qu”) and the wheat amount of about 40% of the water, stir until no dry powder, no bumps, hand knead, drop and scatter is the best. Now it’s almost all done by machine, which requires an experienced master to operate with his senses.

“Qu” material preparation,

3. Step “Qu” billet

The custom of “Dragon Boat Festival tramping” has long been deeply rooted in people’s hearts, and the dog day tramping is conducive to the growth and reproduction of microorganisms, which is extremely beneficial to the cultivation of high temperature “Qu”, and the temperature of the bending operation room is often as high as 40℃.

Artificial trampling pays attention to the operation technique, put the evenly mixed wheat into the mold, press while loading, and stomp the curve with splayed feet. The curved block is required to be dense around, loose in the middle, and shaped like a turtle back, otherwise it can not be completely fermented.

Step Qu billet

4.“Qu”embryo into warehouse

The curved billet formed by “Dragon Boat Festival treading curve” needs to be laid flat to dry, and can be entered into the curved room after the surface has a certain hardness. The curved billet is stacked in the form of horizontal three vertical three, and the new and old straw is stuffed between the curved billet to prevent mutual adhesion. It is not only conducive to moisture dissipation, heat preservation and ventilation, but also provides a good environment for the growth and propagation of microorganisms in the billet.

“Qu”embryo

5. Turn over “Qu” inversion

High temperature “Qu” is the key to the style of Maotai-flavor Baijiu, the “Qu” temperature should be kept above 60℃, but not more than 68℃, generally twice. The workers turn the billet up and down, and replace the old and new straw appropriately to make the billet mature more evenly.

After being placed in the warehouse for 6-8 days, the temperature rises to about 65℃, and the first turning is controlled for two days. After completion, let it stand for 6-8 days, until the temperature drops to 55℃, and perform the second turning.

Turn over“Qu”

6. Dismantling “Qu”

After the completion of the second turn, most of the bend billet has dried, and the bend grass attached to the bend block needs to be removed quickly, and transferred to a ventilated warehouse, and the temperature in the warehouse should not exceed 45℃.

Dismantling“Qu”

7. Dry storage

The cultivated :“Qu” block is transferred to the dry “Qu” bin, and the natural dry storage is more than 6 months before it can be put into production. In the storage process, water and some low boiling point volatile components are lost, making the fragrance more intense. At this time, you can choose some super blocks to store separately, and you can use them as master songs after 3-6 months.

“Qu” Storehouse

8. Grind “Qu”

The mature “Qu” is one of the main raw materials for the brewing of soy Moutai-flavor Baijiu. Before being put into the production of Baijiu,it should be broken, finely ground by the grinding machine, without particles, and finally into powder, the finer the better.

After the above eight processes, it takes at least 3-5 months to produce a qualified Baijiu. The Baijiu is filled with various types of microorganisms, and the flavor contains the secret of the flavor of the Moutai-flavor Baijiu. Almost every Baijiu has its unique recipe and process for making the Moutai-flavor Baijiu, which makes us able to taste different styles of Moutai-flavor Baijiu, and each bite is full of different flavor and charm.

Maotai Town