Fermentation Management for Control of Flavours. Congener Development in Spirit Production

The process of fermentation is more than the transformation of sugar into ethanol and CO2. It is the first opportunity to modulate the aromatic profile of the spirit. This article, will show how factors such as yeast strain and the conditions of fermentation will impact the aromatic profile. This gives the distiller an abundance of various aromas and flavours with which to craft his / her spirit. This article is a summary of the masterclass given by Maryse Bolzon during the last edition of the Spirits Selection by Concours Mondial de Bruxelles 2020.

By Maryse Bolzon – Global Craft Distilling Manager Lallemand Biofuels & Distilled Spirits (LBDS)

In the past, a producer of distilled spirits was not really concerned about the aromatic profile of his distillate as long as it was consistent and showed no off-notes. Nowadays, it is totally different, everybody understands that getting a good distinct spirit involves a controlled process and relevant monitoring.

This article will review briefly some simple, easy to manage key parameters, to modulate the aromatic profile of the distillate from the fermentation process.

The aromatic profile of a spirit is based on complex interactions between congeners such as higher alcohols, esters, aldehydes, ketones, sulphur compounds, etc. Yeast strain, nutrition of the yeast, temperature of fermentation and agitation are parameters which impact the aromatic profile and which allow the distiller to achieve a distinctive and unique spirit.

In a distillery, whatever the size, the only way to produce the components for a distinctive and unique aromatic profile is to use the correct yeast and a good quality substrate under correct conditions in fermentation. It is very important to take time to choose the yeast correctly.

When a distiller selects a yeast strain, he/she has to consider:

– the type of substrate: grain, malted barley, molasses, agave, syrup, fresh juice …

– the character of spirit he / she wants to craft

– the conditions of fermentation and distillation

– the characteristics of the yeast strain, the substrate from where it has been selected and the type of sugar it can ferment.

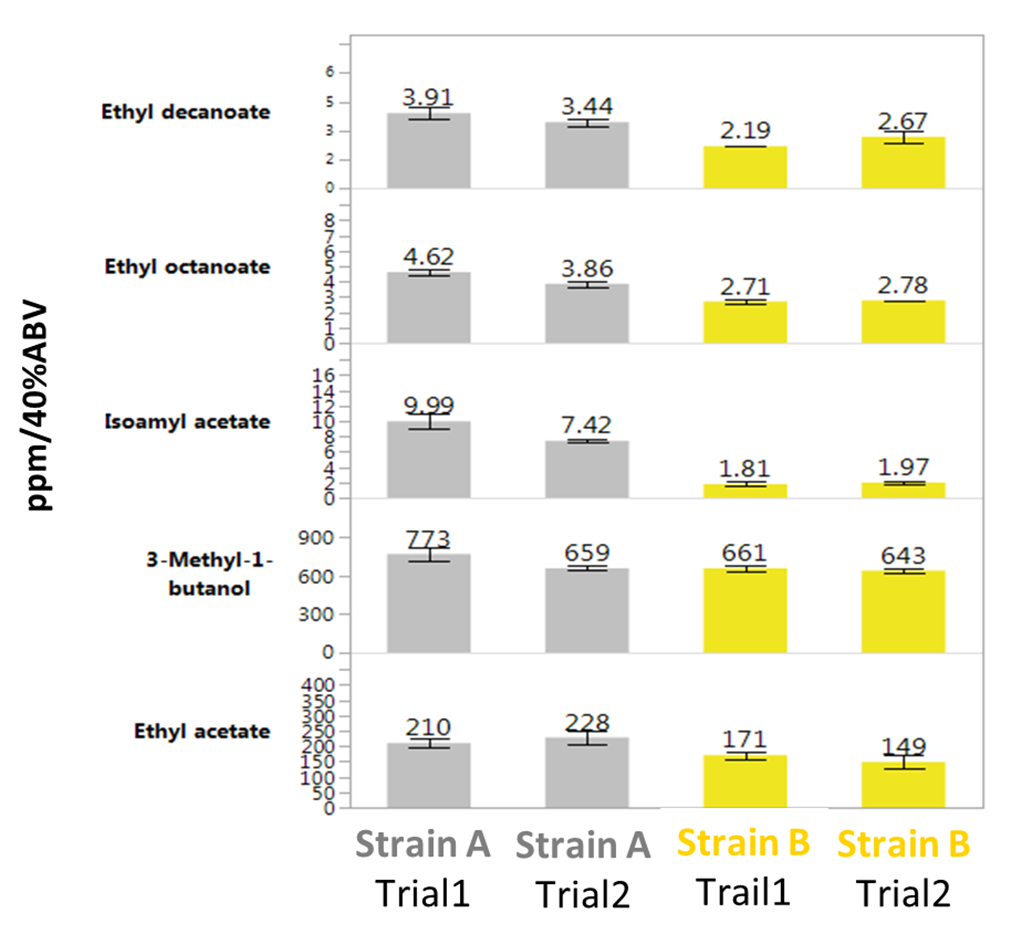

The strain of yeast has a great impact on the aromatic profile. Looking at the results of Graph 1 below, which summarizes trials on a corn mash whisky-type fermentation, the two strains display distinctive aromatic profiles with a significant difference of the concentration of some key congeners. Ethyl decanoate (fruity-like aromas), ethyl octanoate (floral and fruity-like aromas) and isoamyl acetate ( banana-like aroma) which are some of the esters distillers want to produce during the fermentation and to retain during the distillation process. This graph demonstrates also that the strain must be consistent fermentation after fermentation. Consistency is a key attribute to characterize a strain of yeast.

Results on corn mash whisky-type fermentation. LBDS Results.

Results on corn mash whisky-type fermentation. LBDS Results.

Obtaining good, consistent kinetics during the fermentation requires the correct yeast with the appropriate nutrition balance. The first requirement of the yeast is nitrogen so a minimum of 150 – 200 ppm of free amino nitrogen (FAN) is necessary (this level depends on the expected final ethanol content and on the yeast strain) at the start of the fermentation. This nitrogen is taken up as nutrient and involved in the multiplication of the yeast. However, nutrition is more than that, and the quality of the nitrogen source impacts the aromatic profile also. LBDS has worked extensively to obtain a better understanding of how the nitrogen source changes the profile of the spirit. Today, it is know that if the nutrition involves organic nitrogen only, the concentration of phenyl-2-ethanol and methyl-2-ethanol will be higher than with the addition of inorganic nitrogen only. On the other hand, the levels of ethyl formiate and acetaldehyde will decrease with the increase of the proportion of organic nitrogen. These are just some examples but we understand when we combine the various congeners that we will get different spirit according the distribution of organic and inorganic nitrogen used for the nutrition.

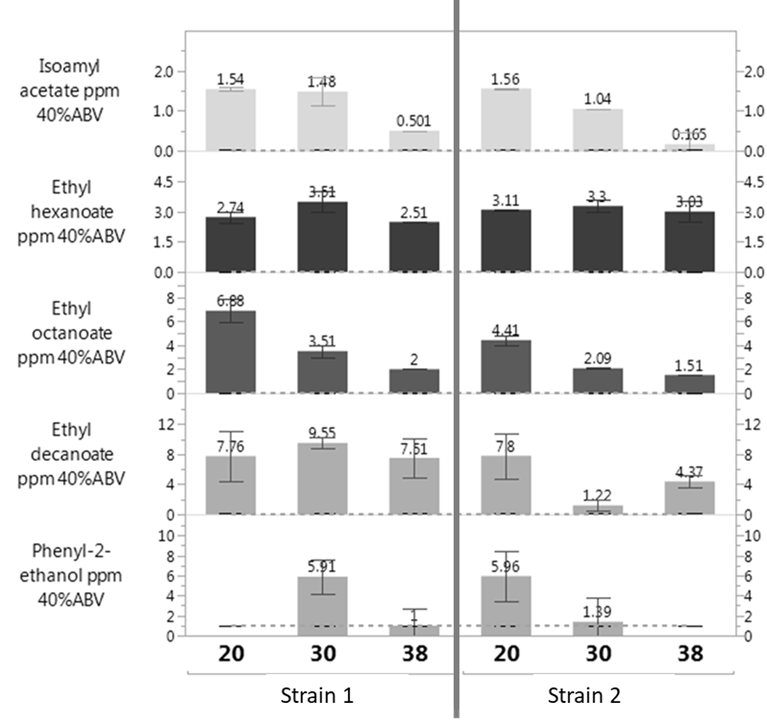

Another parameter quite easy to manage and very impactful on the kinetics and the aromatic profile is the temperature of fermentation. The Graph 2 which summarizes results obtained with 2 different strains at three different temperature 20°C, 30°C and 38°C illustrates very well the impact of temperature. The feedstock used for this experiment is molasses.

Looking at the results each strain displays a different aromatic profile according the temperature:

– Strain 1: the concentration of ethyl octanoate decreases according to the increase in temperature while the optimum of phenyl -2-ethanol is obtained in the fermentation at 30°C;

– Strain 2: the concentration of the various congeners decreases according to the temperature but looking at the phenyl-2-ethanol, its concentration is higher when the fermentations are run at 20°C.

Distinctive aromatic profiles on molasses fermentation. LBDS Results.

Distinctive aromatic profiles on molasses fermentation. LBDS Results.

The last parameter which is easy to manage and also has an impact on the profile of the spirit, is agitation. A moderate agitation throughout fermentation helps the yeast complete its work, is a good way to reduce the acetaldehyde concentration and to increase the fruit-like esters.

To summarize, working on and combining simple parameters such as the yeast strain, the nutrition, the temperature of fermentation and the agitation, can definitively impact the aromatic profile of the spirit.

The last step, which is distillation, allows you to capture and develop new aromas from the precursors and flavours developed by the yeast during fermentation.

Making the right choice of the yeast according the distilled spirit you want to produce and keeping the yeast happy along the fermentation step are the guarantees of high quality final distillate